Shunjia Electronics, magnetic inheritance of the artisan pulse, perpetual symbiosis;

Shunjia Electronics, magnetic inheritance of the artisan pulse, perpetual symbiosis;

This is an extremely ordinary night.

The autumn wind in November brought a slight coolness, and it was already 1am, but at this moment, the production workshop was still filled with the hardworking figures of workers.

Storage, re inspection, discussion, modification

They have been spinning continuously for 36 hours, their sleepless state making their eyes red, but there is no sign of impatience on everyone's face, only a unanimous determination to make the product good.

They are the R&D team of Junjia Electronics and also meticulous craftsmen.

▲ Founder and Chairman of Junjia, Gao Chuangye

From 0 to 1, after more than ten years of ups and downs

Junjia Electronics was founded in October 2011 and is a high-tech enterprise that mainly produces and sells flat transformers, high-frequency transformers, flat inductors, and ring inductors. Its products are widely used in server power supplies, energy storage power supplies, inverter power supplies, charging pile modules, new energy vehicles, communication power supplies, and other fields.

I used to work in the field of PC power supply. At the beginning, we worked with friends on processing, and the team was relatively small. We received a lot of orders and often had to work overnight several times a week. At that time, we didn't have any sales personnel. I took my children out to run the business myself, working as both a driver and a salesperson, and then returning to work as a clerk. This process has happened before. ”When Liu Yonghua, the general manager of Junjia Electronics, talked about the hardships of entrepreneurship, a gentle expression appeared on his face.

▲ Liu Yonghua, General Manager of Junjia Electronics

The battle of victory and defeat requires spiritual foresight. Junjia Electronics has never been afraid. Every time the company encounters difficulties or reaches a bottleneck, it is a cocoon wrapped around itself. Liu Yonghua regards it as an inevitable experience for the company's growth. Only by overcoming these difficulties can the company blossom into a butterfly and move towards a new level.

After more than a decade of growth and refinement, Junjia Electronics' products have become increasingly diversified, and more and more customers are turning to Junjia Electronics for solutions to product volume or efficiency issues. Because Junjia Electronics' products have the characteristics of small size, high power, and high efficiency, in the trend of high-frequency products, customers not only need to compress the volume, improve efficiency, but also solve the problem of temperature rise. Junjia is able to professionally help customers deal with these issues.

Committed to solving the pain points of magnetic components for new energy

In the context of dual carbon, the replacement of traditional energy with clean energy has become an irreversible trend, and Junjia Electronics is actively seeking to transform into the new energy sector. With the rise of third-generation semiconductor materials, customers have put forward high-frequency requirements, which has made Junjia Electronics more aware of the importance of improving product performance.

Junjia started to engage in the production of new energy products four or five years ago. Liu Yonghua said, "At the beginning, we focused on industrial products. We transformed with the transformation of our customers, and with the increasing clarity of the national 'dual carbon' target policy, we were able to do these things more clearly. When new energy customers come to us, we will try our best to meet their requirements in terms of product research and development, delivery, and quality

At present, Junjia Electronics mainly has flat transformers, high-power flat inductors, and flat wire wound common mode inductors in the field of new energy. The products are mainly used in energy storage power supplies, inverter power supplies, automotive electronics, lithium battery production and testing equipment, etc. They can solve customer pain points from four aspects: smaller volume, lower losses, lower temperature rise, and higher efficiency.

▲ Junjia Inductive Transformer Sample

Last May, a customer who made automotive powertrains approached us. At first, the inductance on their powertrains was very large, and after adjusting the performance of the entire product, they found that there was no place to fit inside the car. So we helped him design a small flat wire inductance. When we sent the first version of the sample, the temperature rise was a bit high, but later we adjusted the second version according to his needs. In July, I drove it to the customer's place and helped him solve the problems of volume and efficiency. The temperature rise also met the requirements, and the customer was really moved

Liu Yonghua smiled happily when talking about solving customer problems. "He said that without your participation, we wouldn't know how to communicate with the car manufacturer and move the location. Without your help, our project might not have been successful. I have also received good news from the customer these days that their product is ready for mass production

Ensure product quality through daily production management

Since its establishment, Junjia Electronics has adhered to the quality line, producing safety products and ensuring product quality through daily production and management.

Junjia's magnetic core supply chain is mainly composed of suppliers represented by Dongci. Liu Yonghua said, "We choose well-known brands in China according to customers' needs. The biggest feature of our suppliers is that they can quickly serve Junjia."

Junjia has a comprehensive supplier evaluation and supervision system, selecting suppliers based on the 16949 standard. Newly imported suppliers will organize on-site inspections for procurement, engineering, and quality control before they can be imported. They will also sign quality management agreements, environmental protection agreements, procurement agreements, and other agreements with suppliers.

The strict supplier selection system also leads to some suppliers being excluded from the supply system due to substandard quality. A few years ago, common mode inductors were used in PC power supplies, but some suppliers were unable to achieve the required inductance or experienced significant deviations. We just told him that we're sorry, but this product doesn't meet our requirements. ”Liu Yonghua added, "When the company grows to a certain extent, we basically cooperate with the original factory and rarely find agents. We are worried that some agents may cause product instability due to different brands

In production, Junjia always adheres to zero defect management of products, allowing production personnel to build a closed loop and pursue lean management. At the same time, in the design process, classification management is carried out based on correlation, promoting standardization, visualization, and dynamic monitoring of people, equipment, materials, processes, environment, quality, and safety, ensuring smooth production, efficiency optimization, and stable quality.

Thousands of sets of molds, with a delivery time of seven working days

Currently, the R&D personnel of Junjia Electronics account for 10%, and the R&D amount is 5% -6% of the annual revenue. There are 2 invention patents and more than 20 utility patents.

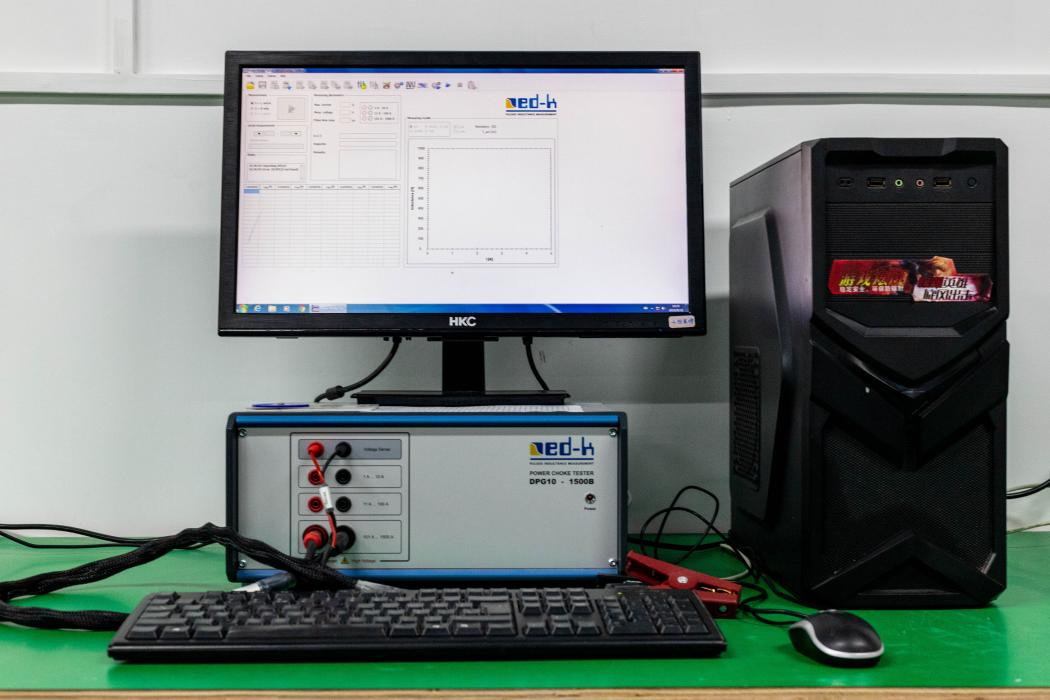

Junjia Laboratory is equipped with a complete set of reliability testing equipment. In addition to the conventional high and low temperature, cold and hot shock, constant temperature and humidity, salt spray, vibration, and tensile testing equipment on the market, it also adds a 1500A DC overlay tester. These devices and detection capabilities can quickly provide customers with real and effective experimental data, assist customers in quickly solving technical problems, and provide strong support in product selection and design direction.

▲ Junjia Electronics Lantai Tester

In terms of research and development sampling, Junjia is able to independently design inductors and transformers, assisting customers in quickly selecting and developing new products. In the development of flat transformers, Junjia has already developed a complete range of flat wires and copper wires, which can quickly provide samples for customers to test, shorten their product development cycle, and reduce development costs.

Junjia has thousands of sets of molds for inductors and electronic transformers, with a large selection space, fast production, and the ability to help customers save on initial development costs. We can provide the customer with a basic design plan within 1-2 working days and samples within 7 working days, which is a promise we can make to the customer, "said Gong Changhong, Chief Engineer of Junjia Electronics.

▲ Gong Changhong, Chief Engineer of Junjia Electronics

Customers only need to provide us with basic parameters, and we can independently help them complete the transformer design to meet their requirements. With the development of the new energy industry, high-power, miniaturized, and modular devices have become the mainstream trend. Although traditional transformers designed by some customers are difficult to produce and have high production costs, Junjia is still able to deliver them excellently.

Junjia continuously optimizes traditional transformers on the basis of existing ones, quickly tests good samples, and begins to apply them in small batch markets. The current 800W flat panel transformer can achieve a height of less than 20mm, and in the 100W-180W PD fast charging project, Junjia can achieve a height of less than 19mm.

New starting point, new journey, new glory

Time never stops, and Jun Jia continues to write new chapters on the road ahead. In April 2023, Junjia moved into a sizable "exclusive courtyard" factory building in Qingxi Science and Technology Innovation Park, equipped with three buildings: office/research and development center, manufacturing center, and employee dormitory. The products of the new factory focus on magnetic components for energy storage, photovoltaic micro inverters, automotive electronics, big data processing centers, lithium electrical production and testing equipment, and other fields.

Liu Yonghua said that the newly relocated industrial park distinguishes research and development, manufacturing, quality, warehousing and finance, and the departments are independent and coordinated with each other. The production line is divided into four parts. Firstly, it is responsible for producing flat transformers and rail transit products. In the field of new energy, it mainly produces semi trial and semi research and development products; The second is large-scale potting products; Thirdly, there are specialized workshops for flat transformers that have already been produced in large quantities and stably; The fourth is traditional transformer products. Each workshop has 4 production lines, a total of 16. Currently, the utilization rate is only 50-60%, and there is still a lot of room for improvement

The operation of the new factory has not only increased production capacity, but also greatly improved management. Liu Yonghua said, "The magnetic material warehouse is very clearly distinguished. The finished product warehouse is the finished product warehouse, and the material warehouse is the material warehouse. We have also strengthened the management of the warehouse: temperature and humidity detection meets the standards, temperature sensitive logistics establish a constant temperature and humidity warehouse, visual color management, etc." In terms of quality, unlike the previous scattered quality management, the new factory has established a complete quality center, and products can be fully controlled from feeding, shipping to full inspection. In terms of production, each production line workshop can be connected or isolated, so that employees will not cross over and affect the normal operation of other production lines.

Currently, Junjia has established production bases in Dongguan, Nanxiong, and Lechang. We have made incremental layouts for production lines in Nanxiong and Lechang respectively, with a new production workshop built in Nanxiong and an improved automation level in Lechang, such as upgrading and adjusting soldering machines and testing equipment.

In terms of division of labor, the production base in Dongguan is responsible for operations, from business order taking, research and development, quality inspection to warehouse management, while Lechang and Nanxiong are managed in a pure production mode. Lechang and Nanxiong only equip the production workshop to produce products, and then hand over the goods to the Dongguan headquarters for quality inspection. We have established a full inspection line in Dongguan, and if there are any problems with the products produced, we will conduct a full inspection again before storing and shipping them, "Liu Yonghua explained.

Accelerate the development of enterprises by continuously attracting talents. In the past two years, the development of Junjia has become increasingly rapid, and its current revenue has exceeded 100 million yuan. Junjia obtained ISO and IATF16949 certification at a very early stage, and now has been honored as a national high-tech enterprise and an innovative enterprise in Guangdong Province. This year, it has also applied for the Guangdong Province Specialized, Refined, Special and New Enterprise.

When it comes to future planning, Liu Yonghua stated that Junjia plans to apply for the Guangdong Province's specialized, refined, and new enterprise this year, with the aim of transforming and upgrading its products towards specialization, refinement, and specialization, and promoting automation, intelligence, and digitization of production. I hope to establish a partnership platform, industry university research base, and engineering technology center in the next two to three years, which can achieve the advantage of expanding production scale and make Junjia a leader in green magnetic energy. This is what I most want to do

This article is an original article by Bilibili Information. If you want to reprint it, please indicate the source and author information before the article. Otherwise, legal responsibility will be strictly pursued.

Consultancy

Learn more