Shunjia Electronics, magnetic inheritance of the artisan pulse, perpetual symbiosis;

Shunjia Electronics, magnetic inheritance of the artisan pulse, perpetual symbiosis;

In the current wave of digitization, digital power, as the infrastructure supporting key technologies such as big data and cloud computing, has attracted much attention in the industry for its efficiency. The importance of the quality and technological level of magnetic components as the "blood vessels" in these power systems is self-evident.

Junjia Electronics, with its outstanding technical strength and profound industry accumulation, has provided customers with multiple excellent digital power product solutions in recent years. Today, the reporter from "Magnetic Components and Power Supplies" interviewed Gong Changhong, the deputy general manager of Junjia Electronics, to listen to his story of how Junjia Electronics carefully creates every magnetic component and solves problems for customers.

Breaking through passive efficiency and jumping to 99% to win the market

For a long time, magnetic component companies have been producing products that meet customer needs based on designs provided by power supply companies, which has put them in a passive position. However, due to the fact that power design engineers do not fully understand the latest technology of magnetic components, sometimes they cannot design the best results.

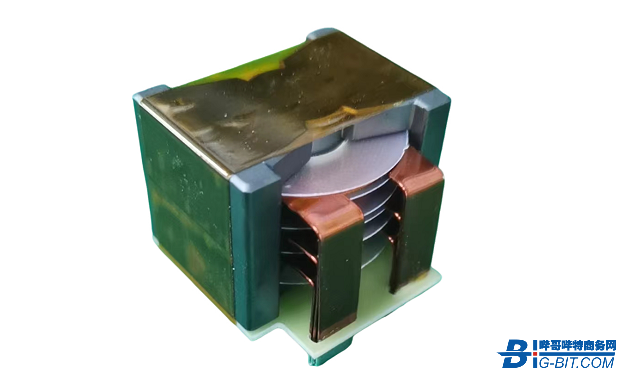

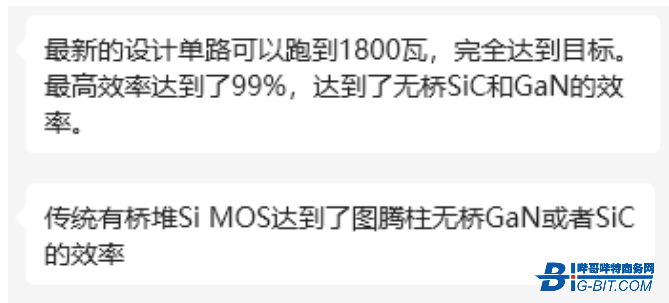

Gong Changhong said that a customer had previously designed a digital power supply and hoped that Junjia would produce all magnetic component products. But we found that the power supply design provided by the enterprise, which uses bridge free PFC and GaN solutions, not only has high cost but also limited efficiency, which cannot maximize the performance of magnetic components. So we actively participated in the optimization and transformation of product design, using innovative methods such as switching to active PFC and utilizing magnetic integration technology to change the design structure of magnetic component products, successfully increasing efficiency from the initial 93% to 99%! Meanwhile, due to the reduction in the use of gallium nitride materials, the cost of magnetic component products has significantly decreased.

Magnetic components for digital power supply field launched by Junjia

This technological breakthrough not only brings more competitive advantages and profit margins to customers, but also demonstrates the strong strength of Junjia Electronics in the field of magnetic component technology.

Overcoming technical difficulties and taking multiple measures to assist product upgrades

However, the process of participating in product development is not always smooth sailing. Gong Changhong frankly stated, "With the increase in frequency of terminal products, the loss of magnetic cores and wires will also increase, which is a significant technical challenge for our magnetic component enterprises. To solve this problem, we will cooperate with suppliers to jointly seek ways to reduce losses. In terms of wire materials, we have strict control over volume and size. In order to cope with the skin effect brought about by frequency increase, magnetic component enterprises need to use finer wires and meet certain size requirements

In addition to quality control of raw materials, Junjia Electronics also plans to add 3 to 5 R&D personnel this year to further expand the size of the R&D team. It also plans to introduce new equipment and software to meet the production technology needs of magnetic components such as flat panel transformers and PFC inductors in the digital power supply field.

Quality is king, customers trust, orders are full

Continuously launching high-quality magnetic component products has earned Junjia Electronics the trust of customers. It is reported that the order volume in the digital power supply field of Junjia Electronics continues to rise this year, with a year-on-year increase of 30% -50% in order demand in the first half of the year. In order to meet production needs, Junjia Electronics also has two dedicated lines at its Shaoguan factory for producing flat and flat PFC inductors for digital power supplies, with a monthly production capacity ranging from 250k to 300k.

▲ Customer feedback on Junjia products

Gong Changhong said, "The biggest recognition our customers have for us is that they will continue to place orders with us. One customer has placed multiple orders with us since our cooperation in 2022, and they believe in our strength and ability, and are willing to entrust more orders to us for processing

It is worth mentioning that Junjia Electronics' first order in the digital power supply field also came from customer recognition of its products. In 2019, the country had not yet vigorously proposed the development strategy of "new infrastructure and new energy", and magnetic component enterprises mainly focused on the consumer electronics field. At that time, Junjia Electronics mainly produced PC power supplies because customers recognized their products. When customers wanted to launch digital power products, they approached Junjia again, hoping that Junjia would provide the magnetic components used in digital power supplies, thus opening Junjia's chapter in the field of digital power supplies.

Looking into the Future, Continuously Innovating for Development

With the development of big data and cloud computing, industrial and commercial applications cannot do without the support of digital power. Gong Changhong said, "In the future, digital power supplies will pay more attention to improving efficiency and reducing costs. To achieve this goal, we will continue to increase our research and development efforts and promote technological innovation! Next, we will continue to deeply cultivate this market, strive to expand large customers, and provide them with more stable and high-quality services

This article is an original article by Bilibili Information. If you want to reprint it, please indicate the source and author information before the article. Otherwise, legal responsibility will be strictly pursued.

Consultancy

Learn more